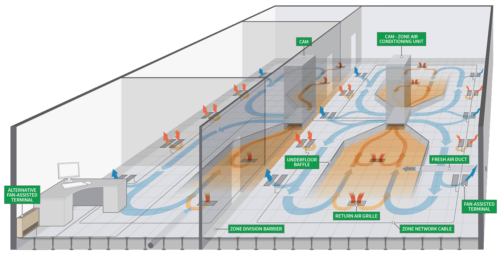

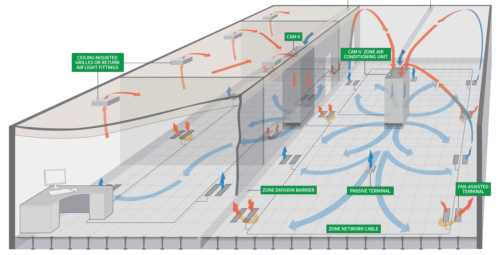

Underfloor air conditioning (UfAC) systems make use of the plenum beneath a raised access floor to create the air ventilation zone, eliminating the need for ceiling based services and associated duct and pipework.

Each floor is divided into zones of up to 300m2 depending on the potential use and occupancy density of the area.

Each zone is supplied with chilled or warmed air by a zonal air handling unit or CAM (Conditioned Air Module) and the conditioned air is then delivered into the space using a recessed (Fantile) or floor standing fan terminal.

Air travels back to the CAM for re-conditioning either at floor level via the plenum (CAM-C), or at high level (CAM-V). Both CAM-C and CAM-V systems can be configured to be either chilled water (CW) or direct expansion (DX).